We can provide oligonucleotide synthesis machine system to meet your needs during key areas of oligonucleotide API production, such as synthesis, purification and ultrafiltration.

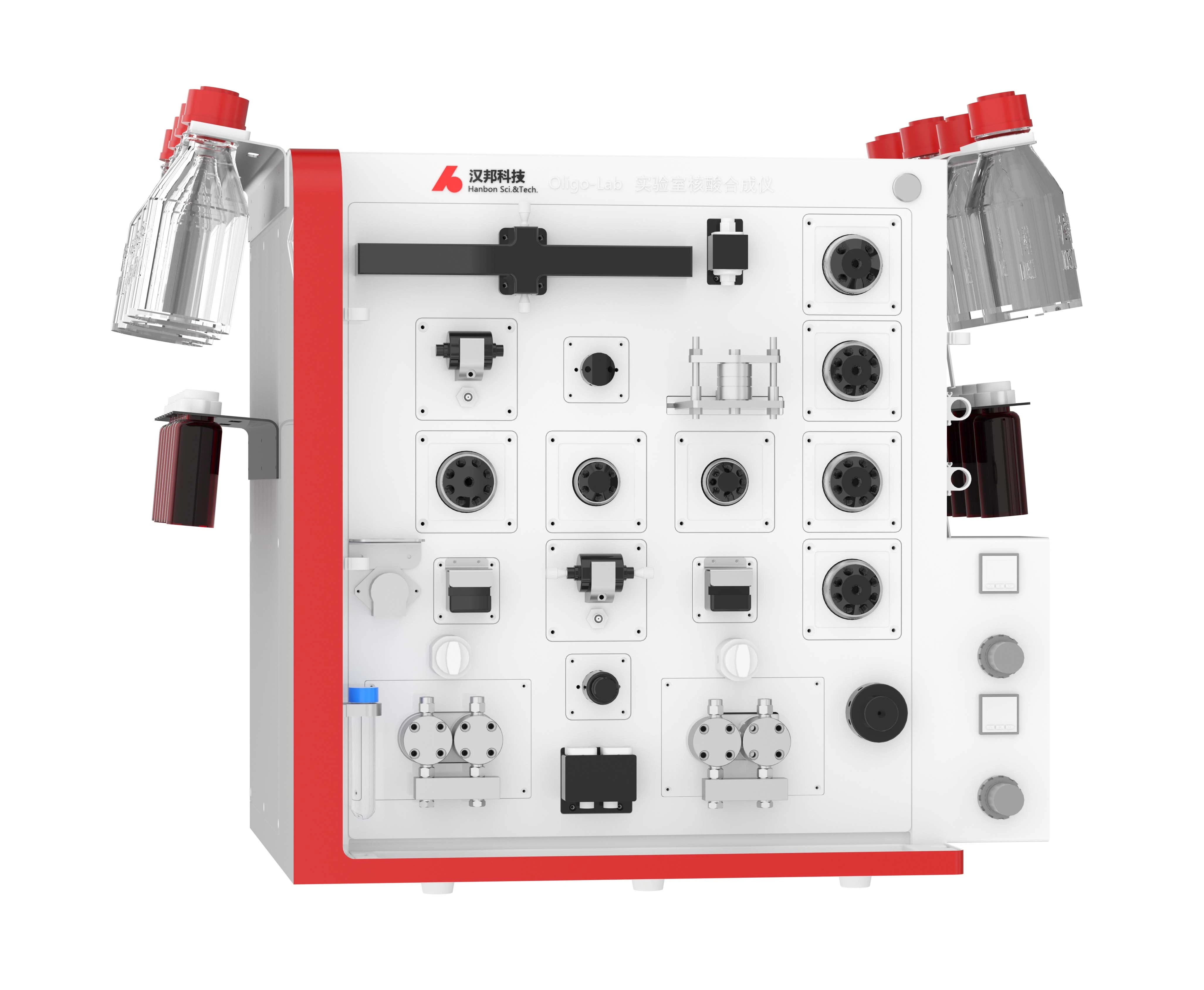

In the synthesis stage, we can provide different sizes of synthesizers to meet your needs in different stages of optimization and next step scale-up, from laboratory level to industrial production level;

In the purification stage, whether you choose reversed-phase chromatography or ion exchange methods, we have the corresponding equipment for you to choose from;

In the ultrafiltration stage, we can also provide different sizes of equipment to meet your needs for salt exchange concentration.

In a word, with Hanbon, you can find the system that matches your need for your oligonucleotide production process.

Most oligonucleotides are currently synthesized using automated oligonucleotide synthesizers, which employ solid-phase synthesis and require phosphoramidite monomers. For example, the phosphoramidite monomer for DNA synthesis mainly consists of bases, deoxyribose, 2-cyanoethyl 5'-DMT and 3'-terminus, and diisopropylamine group, while the phosphoramidite monomer for RNA requires protection of 2'-OH to prevent cross-reaction between 2'-OH and 5'-OH in solid-phase synthesis, and the protecting group is usually TBDMS. Solid-phase synthesis is frequently used nowadays, the traditional solid-phase carriers were controlled microporous glass beads (CPG), but the loading capacity was limited, only 70-80 μmol/g. Nowadays, more high-loading capacity solid-phase carriers are used, and the loading capacity is generally up to 250umol/g~350umol/g.